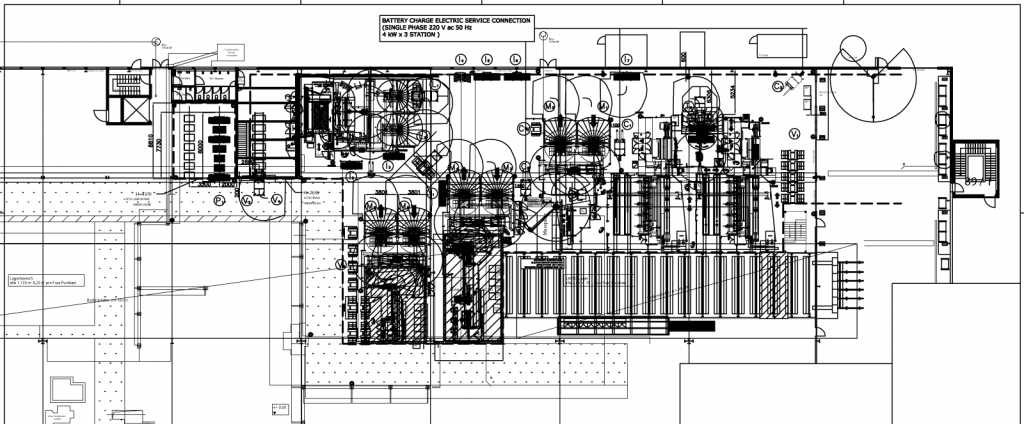

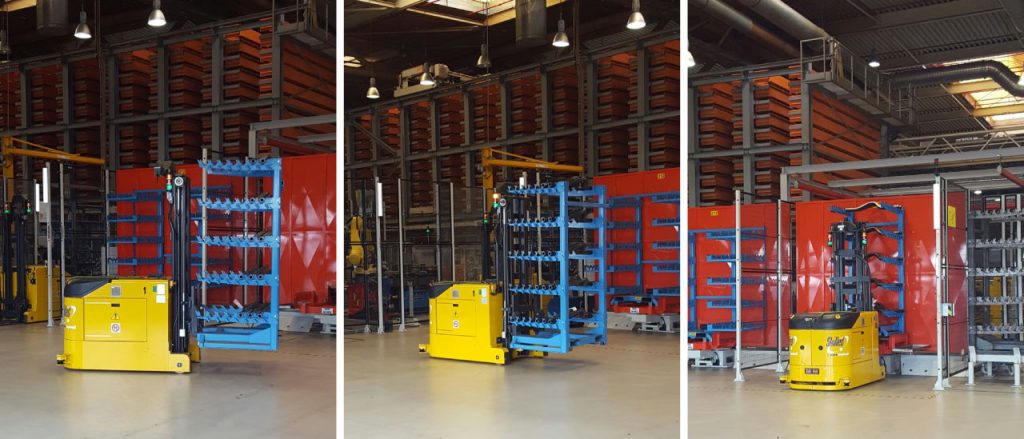

The AGCO Corporation has recently integrated a new production department in its main European factory near Asburgo – DE, where are built large farm tractors. This departmernt has been completely automated with robot islands for cutting and processing metal structures and with three LGVs for handling all semi-finished parts. The introduction of LGVs allowed the handling of materials through all the stages of processing up to the warehouse, without the use of classic forklifts, thus creating a department with high safety standards.

A software for traceability of all processes and the flow of components ensure that every mission is performed by Skilled LGVs by optimizing and respecting the times of the various processes, thus increasing the productivity index of the department. The project, completed in 2017, was a great example of cooperation between the technical teams of experts and the customer, who have faced and implemented together innovative solutions, never used before in the manufacture of agricultural machinery.

AGCO is a global leader in the design, manufacture and distribution of agricultural equipment, based in Duluth, Georgia, United States, with a net sales of approximately $7.4 billion (2016). AGCO products are sold through five core brands, Challenger®, Fendt®, GSI®, Massey Ferguson® and Valtra®, supported by Fuse® precision technologies and farm optimization services, and are distributed globally through a combination of over 3,000 independent dealers and distributors in more than 150 countries. The Corporation delivers agricultural solutions to farmers worldwide through a full line of tractors, combine harvesters, hay and forage equipment, seeding and tillage implements, grain storage and protein production systems, as well as replacement parts.